Lithium batteries – How can you tell the good ones from the bad ones?

Excellent lithium batteries are available on the market. Thanks to their exceptional qualities and advantages, the general public has discovered them, to the point where now, all outdoor users are crazy about them. Unfortunately, these good batteries have paved the way for the production of poor-quality batteries. These batteries have made inroads on the market by claiming the same advantages as those of quality products, the very ones that have been honoring the lithium technology developed by Hydro-Québec since 1994.

The problem: Lower quality batteries won’t let you enjoy the benefits of lithium for long. In fact, even if you pay less for them up front, they will end up costing you more than lead acid batteries. Why? Because of their major defects.

POOR QUALITY BATTERIES ABOUND ON AMAZON, ALIEXPRESS AND LOCAL RETAILERS.

The solution: By choosing a lithium supplier that selects its components with the utmost care, you will ensure that you will enjoy your investment for at least 10 years, if not certainly more. Here are the 3 main criteria to consider when evaluating the quality of a lithium battery.

QUALITY OF LITHIUM CELLS

The cells must come from a recognized producer, whose reputation is unequivocal, verifiable and whose products are certified by internationally recognized standards. There are 3 main families of cells. Each one has advantages and disadvantages depending on the environment of use (climate, vibration, etc.). The choice of the type of cell will have a major impact on the quality of the product, in the long term.

You may be wondering how the entry-level cells will perform. Keep in mind that a lithium cell is a living component, constantly reacting. Exposure to cold will change the internal chemistry of the cells: impure metals can deposit at the electrodes, causing a drop in performance. In concrete terms, to give just one example, the cell’s voltage will drop much more quickly during the next discharges. In addition, even without the cold exposures, a cell that is not quality certified may become deformed during the cycles it undergoes during its useful life.

QUALITY OF ELECTRONIC COMPONENTS

The electronics allow the full potential of the battery capacity to be realized and make it possible to use it safely for its entire useful life. Once again, it is imperative to choose manufacturers known for their reliability.

In poor quality batteries, you will find electronics that are all bad. The mosfets, which are highly stressed during charging and discharging, will crack with the accumulation of cycles, making the battery immediately unusable.

It is also important to know that lower cost batteries will not have polymer treatment on the components of the electronic board. Thus, in the medium term, the oxidation of metals will break the microcircuits and soldering and eventually damage the components, including the microcontroller.

ASSEMBLY ENGINEERING

Engineering is the pillar that will bring all the elements together in the same battery unit, in addition to bringing some details to the assembly level. It’s really important!

“I bought a Volthium battery for my caravan last summer. I am very satisfied with it and I really appreciate the service I received. The people at Volthium are very knowledgeable about their products and, most importantly, they take the time to explain the components and operation to their customers and how they work. “

Yves Choquette, electrochemist and passionate caravanner

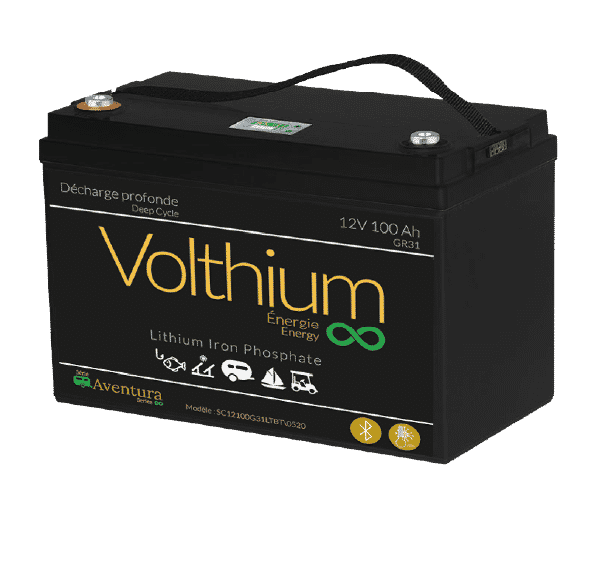

Volthium batteries have many advantages that make all the difference. For example:

- All battery components and cells are soldered.

- The wire gauge is always higher than the required standard.

- The batteries have a heating device for cold weather and an anti-shock system to counter vibrations.

- Not to mention the exclusive Volthium advantage: the custom design of a housing with free access to the electronics. The latter gives you the assurance that you can enjoy the product for 15 years or more. If you have several batteries in parallel and one of them breaks, you can have the broken battery repaired easily.