VOLTHIUM TECHNOLOGY

Innovation and excellence are at the heart of our daily life at Volthium Energy.

Constantly seeking to push the boundaries of technology to offer ingenious and high-quality products. to offer the most efficient and sustainable products on the market.

CELLS LIFEPO4 OF HIGH QUALITY

The quality of the battery’s internal cells is extremely important. High-quality cells ensure the durability and efficiency of a lithium battery. For lithium batteries, there are three main types of cells as well as different grades of cells.

At Volthium, all our batteries are made of the best grade cells available on the market (grade A+) and are UL1973 certified. Our ultra-compact batteries are made up of cylindrical cells and all our batteries over 50 amps are made up of prismatic cells.

Our cell supplier is renowned for its contracts signed with the Volkswagen Group, Tesla, BMW and LG.

Among the different cell technologies on the market, our selection was based on the needs of our users.

Thus, the cells of our batteries are the best on the market :

- Maximum resistance to humidity, cold and temperature variations

- Shock and vibration resistance

- More than 6000 cycles at 80% discharge (1C). More than 3000 cycles at 100% (1C).

- 99.99% internal metal purity

- Delivers 1C continuous power and Peak 300A

- No cell deformation during intensive use

- Ensuring that each cell is “matched” for perfect balance

BUILD QUALITY

While it is true that many lithium batteries look the same physically, it should not be forgotten that the battery components show a level of engineering and are a guarantee of quality.

At Volthium, we have brought together the best components in the lithium battery industry to offer products that are second to none on the market. Our batteries are designed and designed to last longer 15 years in an extreme environment and climate such as the one Canadians face.

- Protective mold for each cell

- Adhesive additive on each bolt

- Fully welded cells

- Internal self-heating system (optional)

- Superior Gauge Conductive Bars and Wiring

- Protection of electronic components by polymer gel

- Accessible BMS Room

- Communication port integration

In this way we offer the batteries with the best energy density, saving considerable space and weight. We also make sure to always provide the best ratio between capacity energy versus dimension.

FULL CONTROL

QUALITY

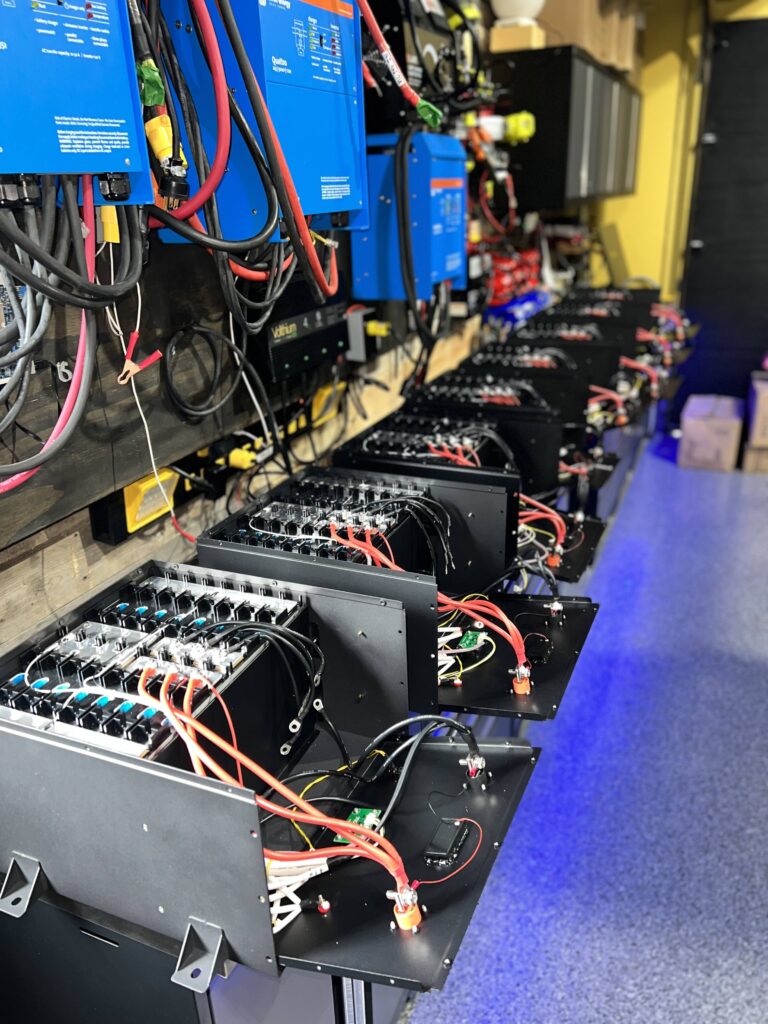

At Volthium, our batteries are assembled according to our own specifications.

Most of our competitors rely on Chinese manufacturers and have no control over the quality of the products. Unfortunately, these cannot expect a product that will be reliable and whose design will be standardized over time. So that’s the difference. We program the electronics here, and buy each of the materials independently, in order to have end-to-end control over the final product.

CUSTOM-MADE PRODUCT

FOR OUR CUSTOMERS

The products we sell are tailor-made to effectively meet the needs of the of our customers. We enable us to respond in a unique and unparalleled way in the commercial and industrial sectors.

Here are some examples:

- Development of a self-heating system and protection against cold load. These innovations make it possible to meet the demands of extreme climates such as the Canadian winter.

- Development of cooling systems to protect batteries from extreme heat and increase the operating temperature range

- Development of exclusive battery housings. All our batteries offer Access to the internal battery management system (BMS). Many advantages derive from our exclusives:

– EEconomical and ecological

– Extended service life (more than 15 years).

-Reparable - We have made waterproof display device in order to make it more durable.

- We integrate different communication modules on our batteries.

- Bluetooth: Charge Level (%), Temperature, Ammeter, Voltage, Number of Cycles

- ADC: Compatible directly with Victron device communication (VE. CAN)

- RS485: Other devices, such as Solark devices, Volthium software (windows), or data collection systems.

- For the transport component, as most of our roads are worn, we have added internal mechanisms to limit the effects of vibration so that the internal parts always remain in place and tight.

BMS

The battery management system (BMS) plays a major role in ensuring safety andefficiency of a lithium battery. At Volthium, we select the best BMS on the market to offer the most technologically advanced batteries on the market.

Several criteria can be used to evaluate the quality of the BMS:

- Quality of Mosfets: Heavily used during charging and discharging, they accumulate a lot of heat and must therefore be of high quality to be able to withstand temperatures above 100 degrees Celsius for peak periods (30sec to 15 min).

- Materials used: We use stainless steel instead of aluminum to prevent oxidation due to moisture over time and temperature variations.

- A coating layer on the PCB components.

At Volthium, 5 layers of polymer cover the printed circuit boards to protect the components from temperature differences and corrosion in the event of an air leak. - Microcontrollers: Texas Instrument is our supplier for processors and micro-controllers on the BMS. Texas Instrument is recognized and renowned in the industry, particularly through its contracts with NASA and the U.S. Army.

- Temperature Probe: 2 temperature probes are inside the battery for equal temperature control.

- Programming and rules: The quality of the programming and algorithms ensure the reliability of the battery.

Indeed, temperature management, the implementation of overcharge/undervoltage protection and the intelligence of cell balancing contribute to the reliability and longevity of our batteries. - Product Control: The batteries are programmed at our premises in Quebec, Canada and this allows us absolute control over the behavior of the battery.

The selection of the best components available on the market allows Volthium to always offer the best in terms of quality, reliability, innovation and discovery to our customers.